The Preferred Turbine -3 conversion consists of many improvements to the operational safety, reliability and usefulness of the DC3/C47 aircraft.

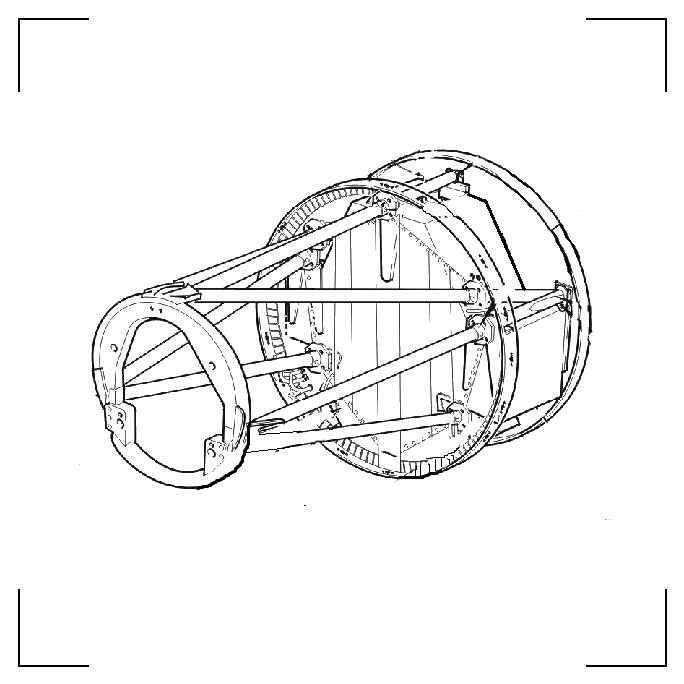

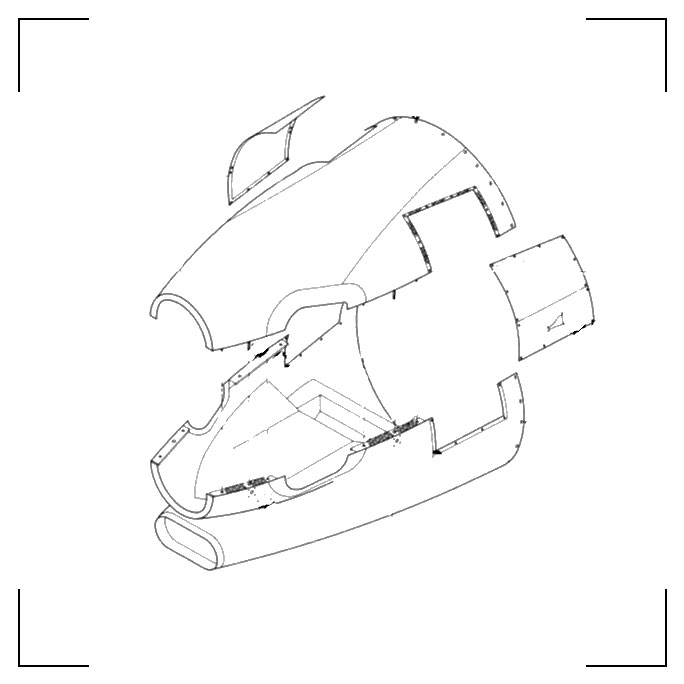

The original radial engines are replaced with Pratt and Whitney PT6A-65AR or -67R turbine engines. New Hartzell 5 blade full feathering and reversing propellers are installed. The fuselage is stretched and the center section and wings are reinforced to increase the max takeoff weight to 29,000 lbs. The electrical system is completely reworked, hydraulic system is updated and a new instrument panel is designed to the customers specifications. A new light weight floor and kydex interior liner are fitted. Multiple brownline tracks are installed to secure cargo and various equipment.

During the conversion process the airframe is throughly inspected.

Skins, floor beams and other structural members are replaced as needed. ADs and Service Bulletins are complied with to bring the airplane up to current inspection requirements. Any customer requirements for mounting equipment or special systems are incorporated.

The work is inspected at various stages during the process, before the airplane is delivered it receives a through final inspection and test flights by our highly experienced crew. New Aircraft Flight Manual, Maintenance Manual, Illustrated Parts Catalog, Wiring Diagrams and Engine and Propeller Manuals come with the airplane.

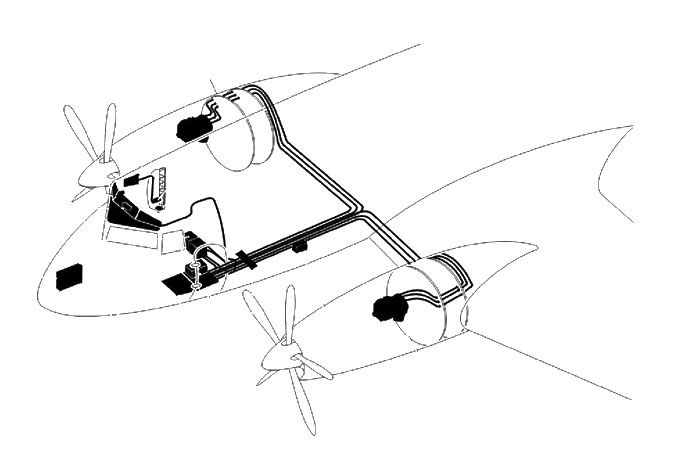

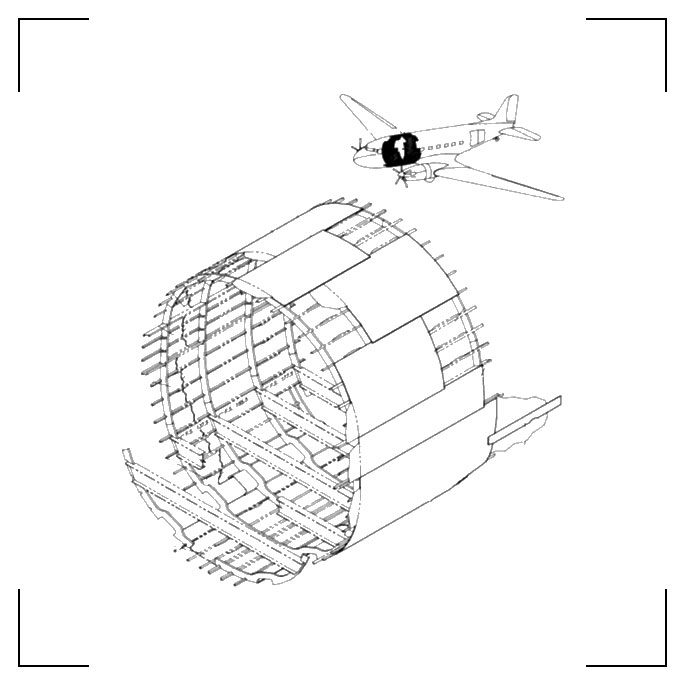

Fuselage Stretch:

The fuselage is stretched 40 inches forward of the center section. This increases the cabin volume to 1225 cubic feet of cargo space. The cabin is 42 feet long, 7 feet wide at the floor and 6 feet 6 inches high.

Electrical System:

All new wiring, circuit breakers, cockpit overhead panels and electrical components are installed. The original 12 volt batteries are replaced with two 24 volt, 48 amp hour sealed lead acid batteries. Nine buses (two left generators, two right generators, two main batteries, two avionics and one hot) handle the electrical distribution. The system is powered by two, 250 amp starter generators. Overhead panels are backlit with rheostats to control brightness. Map and other cockpit lights are replaced with LED lights. LED anti-collision lights, tip strobes and nav lights are standard equipment.

Surface De-Ice System:

Preferred Airparts has developed an FAA approved Flight into Know Icing (FIKI) STC for the Preferred Turbine -3. The system meets FAR 25 requirements. Wing and tail boots are modern glue on boots that eliminate the retaining strips used on the old style pin boots. The boots also extend further back to provide much improved de-icing abilities and are current production. Engine inlets are protected by electrically heated boots and inertial separators keep FOD from entering the engine compressor section.